Amalie Robert Estate Vintage Update: 2024 Harvest After Action Report (HAAR)

Hello and Welcome,

This is the Harvest After Action Report and Photo Journal, Vintage 2024, from Amalie Robert Estate. Approximate reading time 1.25 ARB's (Adult Recreational Beverages); Pictures only 0.50 ARB's.

Murphy, the patron saint of agrarians everywhere, postulated that if anything can go wrong, it will. And the follow-on corollary, that if there is a worse time for something to go wrong, it will happen then. A lesser-known law, but equally formidable, is that nature always sides with the hidden flaw.

Well, not this year. Vintage 2024 was about as perfect as it gets in winegrowing. Up until and including the rapture of The Great Cluster Pluck! Oh sure, we had the minor weather inconveniences that plague everyone. Makes for good small talk while we are performing percussive maintenance on our agricultural equipment.

And after 25 plus years of this agrarian bliss, Ernie has learned that you really only need two tools to fix most things. They are, first and foremost, a hammer (or other energy transferring implement) to bring to bear the ever-increasing force of percussive maintenance, and secondly, a credit card. To quote St. Murphy, “If it jams, force it. If it breaks, it needed replacing anyway.”

In This Communication:

Channeling Vintage 2012

If Everything is Going Well...

The Great Cluster Pluck!

The Harvest Target Package

Calling an Audible

Playing Chicken with Mother Nature

Channeling Vintage 2012

Many avid FLOG readers may recall Vintage 2012. This was a very nice growing season whose resulting wines delivered on the promise of the vintage. But what really made it special was that nothing went wrong. St. Murphy was apparently otherwise entangled with Mother Nature, and the Willamette Valley Pinot Noir wine berries flourished. The harvest window, much like Vintage 2024 was ample and did not present any major challenges. Not that we had time to dilly dally around, but we had enough time to get it done.

If Everything is Going Well…

… You have obviously overlooked something. But we didn’t miss a thing. The key dates in the vineyard happened within accepted tolerances. These dates often trigger vineyard labor deployments and/or mechanization which we also saw to in a timely and effective manner.

The FIRST major peril the winegrower must address is the threat of early season frost from that curmudgeon Old Man Winter and his spry apprentice Jack Frost. The vines, and the winegrower’s income, are greatly dependent upon the survival of the newly opened buds, leaves and inflorescences. Inflorescence will eventually grow into clusters of wine berries, if things go well… If things do NOT go well, a late arriving frost will freeze this new tissue, and the inflorescence will die a frosty death.

Spring in the Willamette Valley Vintage 2024 was about as pleasant as the day is long. It fills the winegrower with great hope to see all of the new growth sprouting from the dormant vines. Jack Frost gave us a pass this year but will most likely return next. The newly opened buds unfurled their leaves to Vintage 2024 and developed unabated. Then it was GROW, BABY GROW!

We begin our climate tracking on the apropos date of April Fools’ Day (April 1st). Most agrarian endeavors involve, at some point, digging in the dirt. Winegrowing is no different. And we find the soil is most receptive to mechanization in the second quarter of the year from April through June.

The viticultural objective is to incorporate the previous year’s cover crop into the soil, thus providing springtime nutrition for our vines. Ernie accomplishes this with his biodiesel burning Italian crawler, a flail mower, chisel plow and rototiller. Then it is right back over those rows to drill in a summer cover crop that favors beneficial insect and nitrogen fixation. As an agrarian, Ernie is fixated with nitrogen fixation. It’s a real fixation that Dena has come to accept. A glass of Pinot Noir helps.

The SECOND major peril facing the winegrower is fruit set, or more commonly known outside the viticultural world as pollination. Wine berries, and grape vines in general, are self-pollinating. Yes, they are willing to entertain a few bees and other insects during flowering, but it is not necessary for pollination to occur. What is necessary for pollination is favorable weather. Warm, dry days with a gentle breeze is as close to a sure thing as you are going to get in the agrarian endeavor.

And we had that. We have since learned that not everyone did. That’s the thing about real estate, the three most important things are LOCATION, LOCATION, LOCATION. When you buy a Willamette Pinot Noir enjoying ideal weather for flowering in June. e Valley vineyard site, you primarily pay for two things. The first is soil, either sedimentary or volcanic based, and the second is aspect. Aspect combines elevation, slope, air drainage and everything else normally associated with the word terroir. And (as is the case in most real estate transactions) God picks your neighbors…

The appropriate and timely application of field labor is critical to the winegrowers success in this stage of the growing season. Specifically, we are tasked with capturing all of the vine’s new growth in 3 sets of catch wires. This is an annual struggle that we engage in with the vines. They have a limited amount of time (and seemingly unlimited energy) to grow enough leaves to ripen their seeds. They work 24 x 7 filling out the trellis. We endeavor to persevere.

We accumulated 749 Degree Days from April 1st through June 30th, as comparatively charted below, and recorded 5.78 inches of rain. The high temperature for this quarter was 91.2 degrees and a low temperature of 39.0 degrees. Flowering commenced on June 11th. While this is interesting in its own right, what’s important to see is what is not there. There are no significant weather events to impair the vines or the development of the newly formed wine berries.

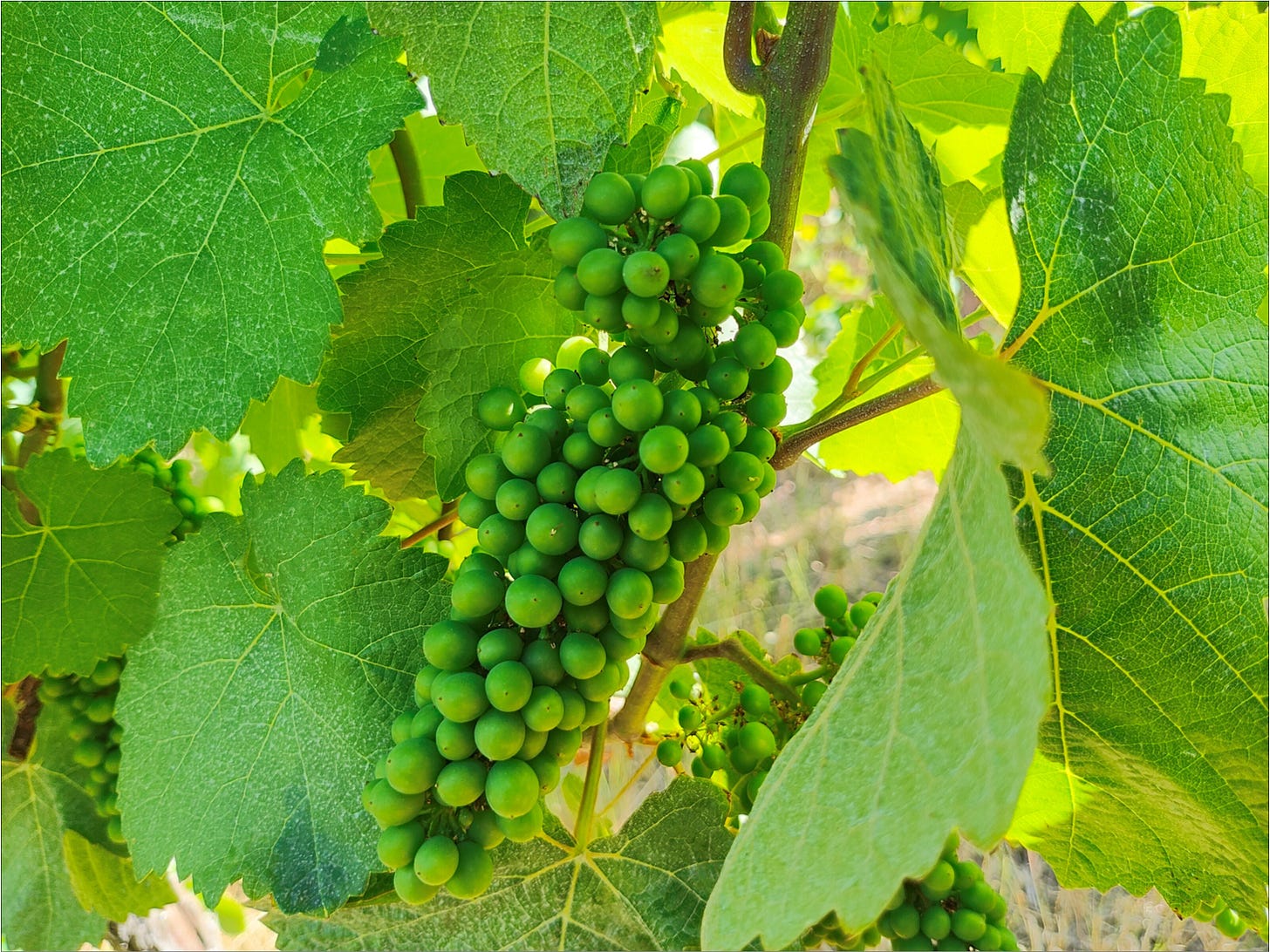

The THIRD major peril is a mildew infection as the wine berries mature. It is now July, and the vines are bedangled with tiny clusters of green wine berries, about the size of a garden variety pea. The vineyard crews are here, and they are straightening out the shoots, raising the trellis catch wires and clipping them into place. The vines are locked in for the duration. They are not going anywhere.

This is Ernie’s busy time. His job is to steward these very young wine berries to The Great Cluster Pluck. His spray program is designed to thwart early season mildew infections and prepare the clusters to ward off our old nemesis botrytis. He also has the responsibility of hedging the canopy as it outgrows the trellis catch wires. To accomplish these tasks in a timely manner over 35 acres of vines he utilizes two tractors. Yes, they are both ITALIAN tractors…

And this is when St. Murphy came to call. Each tractor is set up to perform a specific task. The spray tractor is set up to pull a 300 gallon sprayer though the vineyard at about 2.4 miles per hour. The hedge/mow tractor sports a front mounted, over the row hedger and a flail mower out back to incorporate the cuttings into the grass to feed our worms, various microbes, and their associates.

Then one morning the spray tractor lost the fuel injection pump. It wasn’t really lost. It was still attached to the engine, but it was leaking biodiesel. This is a significant impairment to the successful operation of the tractor, and winegrowing in particular.

According to Standard Farming Procedure, the first repair option is always percussive maintenance, but that thought quickly turned to credit card. And here is the thing about having someone fix something you can’t – you only want them to do it once. It’s not only about the monetary cost, but also about the down time of a critical path machine. At the end of the day, considering all factors and factoring in all considerations, the hi-cost repair option is not always the most expensive.

In the meantime, Ernie was left with a conundrum. How to perform two very different mechanization tasks with a single tractor. The good news (if you can believe it) is that BOTH tractors are Italian! Ernie saw the irony in that after the first adult recreational beverage. It was confirmed on the second.

That meant that the drawbar at the back of the spray tractor would mount on the back of the hedge/mow tractor. The drawbar allows you to tow wheeled implements, like a sprayer, behind the tractor. Why it is called a drawbar, and not a towbar we cannot explain. Not everything in the agricultural endeavor has an answer.

But you cannot pass go, pay your $200 and attach the drawbar until you dismount the flail mower. Fortunately, Ernie did not have to mount the hedger on the spray tractor. That would be a hard “nocando” expressly equivalent to the financial three-letter acronym “NFW” (No Financial Way).

But, Ernie was halfway there. He could hook up the sprayer to the back of the hedge tractor after installing the aforementioned drawbar. But to be able to spray, he would need to remove the front mounted hedger. Right. Of course, to hedge and mow, the sprayer and drawbar would need to be removed and the mower and hedger re-installed.

The spray and hedge/mow program runs on a 7 to 10 day rotation. It takes Ernie 3 days to perform a single spray pass, and then 3 days to perform a single hedge/mow pass. With Dena’s help, it takes a day to configure the double duty tractor from one operation to the other. So, how much sleep does Ernie get every 7 to 10 days? Not counting the time on the tractor, it isn’t a whole helluva lot.

As Ernie was wrapping up his last hedge, there was a glimmer of hope. The summer long injection pump saga was coming to an end. His spray tractor was coming home. Ernie was hopeful this would be a successful end, but that remained to be seen. Once the credit card formalities were taken care of and the delivery rig rumbled up the road, Ernie was out of the house like Ralphie running to the mailbox!

And there it was, as Italian blue as it could be covered in a fine patina of Willamette Valley gravel-road dust. Beautiful! Ernie got to work hooking up the drawbar and sprayer, followed by the electronics needed to tie it all together. Italian agricultural equipment and electronics exist in a world unto themselves.

And it worked! It worked the very first time! And it continued working for the next 3 days! And through all of that, St. Murphy was nowhere to be found. That allowed Ernie to complete the spray program for Vintage 2024. The wine berries were now on their own building sugar and developing scintillating aromas and flavors.

We accumulated 1,584 Degree Days from July 1st through September 30th, as comparatively charted below, and recorded 1.56 inches of rain, mostly in September. The high temperature for this quarter was 104.4 recorded in July and a low temperature of 40.5 recorded in September. Pinot Noir in Flagrante commenced on August 3rd, which is just a few days before the historical average for this sort of vinicultural phenomenon. There were two offsetting weather events that warrant our attention. The first is the July heat spike.

Similar to previous vintages, but with less intensity, there was a heat dome that settled over the Pacific Northwest in early July. The concern here is sunburn on the exposed wine berries. Leaves are the answer to protect the young wine berries, but sometimes the clusters are caught out without any leaf cover. Unfortunately, when the damage is done, it often will compromise the entire cluster and it is then lost to the terroir.

The second weather event to note was the early September rainfall. The vines take this moisture up through the roots and can rehydrate the wine berries from the summer drought. September rainfall can extend the aroma and flavor development with less sugar concentration resulting in lower alcohol potential. That is the good news. The moisture can also enable botrytis to grow inside the clusters. That is the bad news. Once that infection starts, it is game over for the entire cluster. Those wine berries will not make viable wine.

The FOURTH and FINAL peril is now set. We must remove the viable wine berries from their mother vine and transport them to the winery where we will ferment the sugar out of them. That is The Great Cluster Pluck. Moving about 70 tons of wine berries from there to here in a controlled manner. To wit St. Murphy: “Whenever you set out to do something, something else must be done first.”

The Great Cluster Pluck! (aka Kicking Ass and Picking Pinot Noir!)

Vintage 2024 marks the 23rd harvest at Amalie Robert Estate. Been here and done that, waiting for the t-shirts! We have also been the beneficiaries of a lot of help along the way. Everyone that helps you contributes to your success, though not everyone contributes in a positive way.

We have also accumulated a tremendous amount of experience each and every year through unfortunate, but not necessarily uncommon events. You are said to have gained experience when things don’t work out the way you had envisioned. And there is nothing inherently wrong with gaining experience, just try not to make a habit out of it.

Sometimes things work out in a previously identified way, and you acknowledged that possibility with forethought, but did not believe it had a high probability of coming into fruition. This is the world telling you, “I told you so”. A disappointing and disheartening experience.

And then there is the successful failure. This is when things do not work out as you had planned, but the results show great promise. You have succeeded despite your best efforts! This is the kind of experience that doesn’t hurt quite so much. And this type of experience, over an extended timeframe, can lead to great innovation (and occasionally) success. But not usually in the agrarian endeavor.

The Harvest Target Package

Ernie has developed “The Harvest Target Package” as a cumulative response to all of the experience he has gained over the past 23 agrarian years (that is a lifetime in dog years). This single piece of paper relays the entire harvest plan for any given day. It covers contingencies for over or under cropped vines, and variability in the harvest process. And best of all, not only is it numbered, but it’s also color-coded!

Let’s have a look, shall we? The first thing you may notice is that we begin with a map of the vineyard. Each block is numbered and the orientation as well as vine spacing is included. So far, so good. Then we add the date. This little piece of information is oftentimes overlooked, but ignore the date (and rely on memory) at your peril.

Ernie then lists the blocks to be Cluster Plucked in the sequence the plucking is to commence with the first block to be plucked first and the second block to be plucked second and so forth and so on. Each block in the list is color-coded with the block on the map using THE SAME color!

As you scan each block, you may notice the color-coded arrows that indicate where to begin the Cluster Plucking. For example, we may begin at the top of a block and then finish at the bottom for north/south oriented blocks. For alternately oriented rows (these are blocks 1 through 6) we may start at the fence and work toward the ravine, or back to front. The objective is to go from the end of one block to the beginning of another in the most efficient manner for the harvest crew. Ernie drives the tractors, he’s on wheels and can adapt.

And now we get more into the art meets science of The Great Cluster Pluck. First the science. Ultimately, we are going to be filling 3,000 pound capacity fermenters. Assuming an average bucket weight of 20 pounds, this provides us with an estimate of about 150 buckets of wine berries per fermenter. We apportion this out into 4 harvest bins, yielding about 37.5 buckets per harvest bin. Typically, buckets are a little over 20 pounds so we round down to 36 buckets per harvest bin.

As the harvesters are bringing buckets to the harvest trailers, we are sorting out leaves and any less desirable clusters whether it be sunburn desiccation or the odd botrytis infection. We are also paying attention to how full the buckets really are. If they are mounded high, that means they are over 20 pounds, more likely 22 pounds. If they are less than level with the top, closer to 18.5 pounds.

Calling an Audible

As we assess the bucket levels, we may increase our count to 38 buckets per harvest bin to account for “low fills” or we may go the other way to lower the count to 34 buckets per bin for heavy buckets. And at some point during the day, you will hear someone will yell out Pájaros! This is the Spanish word for winged Cluster Pluckers. As in “Here come those flocking Pájaros!” Ernie tries to pick up a few new words and key phrases each year, most of which cannot be published in this forum.

We count buckets because if we overfill a fermenter, the excess juice/wine runs over the top and across the floor into the receptacle of last resort – the drain. Everyone works way too hard to allow that result, so we look at the buckets and adjust our count in the field as needed.

Now we move into trailer math. The first thing to remember is that each harvest trailer carries 3 harvest bins, and the bins are numbered so we can associate them to the blocks. The next thing to keep in mind is that each fermenter holds 4 harvest bins. Finally, we harvest each block in the vineyard separately. A block may take 3 harvest bins or maybe 4.5. We never really know until we roll up to that block and get into the Cluster Plucking.

But what we do know is we are filling a multiple of 12 harvest bins (3 fermenters worth) each day. An easy day is 12 bins. We are running with the shovel doing double-time at 36 bins in a day. Plucking 36 harvest bins worth of wine berries comes out to 13.5 tons. We start at 7:30 am and can usually finish up by lunch time. During harvest, lunch time is defined by when you finish harvest. How convenient!

Playing Chicken with Mother Nature

The Great Cluster Pluck Vintage 2024 began, as it always does, in earnest. The entire month of September was stunningly beautiful. There were no significant impairments to speak of. Whatever sunburn or botrytis infections we were going to get had already occurred. It was our job to sort them out if they came to the harvest bins. And we did.

Cluster Plucking continued unabated through mid-October. Ernie had just one more Cluster Pluck in mind and that was block 13, the Syrah at Amalie Robert Estate. The Syrah is where he hangs it all out there. In competitive shotgun sports, you don’t break 25 targets straight without breaking the last one. And it is a good feeling when you do.

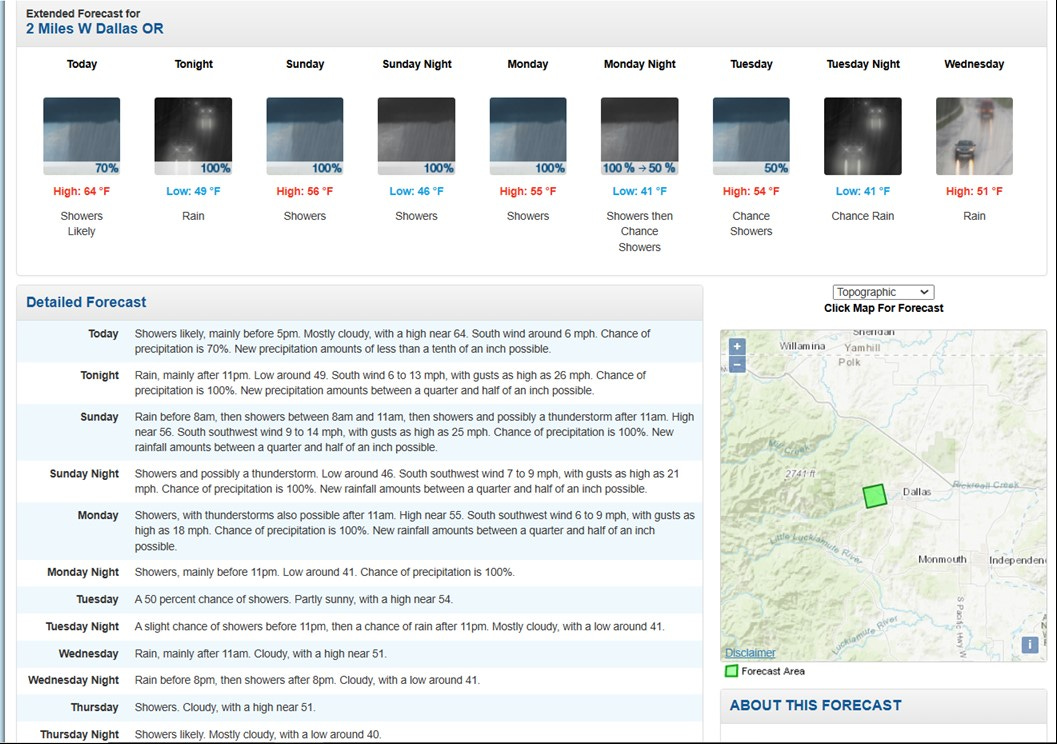

No matter the year, block 13 is Ernie’s 25th target. The week beginning October 21st saw about 0.32 inches of rain, but the forecast was clearing for the remainder of the week. Forecasts become much more accurate as you approach the harvest window. Ernie set his sights on Friday the 25th hoping the impending rains forecasted for Saturday would actually wait until Saturday. And so he waited. That is what it’s like playing chicken with Mother Nature.

Thursday was another beautiful day of ripening. The last one for the Syrah and Viognier. The forecast low that night was 37 degrees. We awoke Friday morning to a very brisk 34 degrees. Those wine berries were going to be fresca!

The dawn broke to clear, glass-blue skies. Man, this is living. The tractors started and the harvest crew was on time. Most likely because there was no place else to go. When it comes to the final days of harvest in the Willamette Valley, we are usually the last pig through the chute.

Block 13 is really 4 blocks in one, 12 rows total. Each 3 row set is a different clone of Syrah. And if you have met Ernie it will not come as a surprise to learn that he picks each 3 row set separately. But there is a very good reason for this. Each clone is remarkably different in physiological composition, and aroma and flavor profile. Ernie tried to explain this to the harvest crew one year. What he ended up with was a little more experience for the next year.

First things first. We take the 3 rows of Viognier in block 12 first, while the buckets are clean. Viognier always sets a light crop, and those three rows did not take long. Then it was top to bottom, move to the next 3 rows, bottom to top, move to the next 3 rows top to bottom. You get the idea.

And then it rained. Not so much on Friday night as we filled two fermenters with freshly plucked, whole cluster Syrah, with a Viognier cluster or two in the mix. But Saturday dawned and brought with it a wall of rain, 0.59 inches to be precise. And that was the plan. That is always the plan. Ernie waits until that impenetrable wall of rain is headed our way, and then ducks out the day before to Cluster Pluck the Syrah and Viognier. If you are going to be bad, you’ve got to be good.

We stop recording climate data on the last day of The Great Cluster Pluck. We believe it is important to track the climate as long as we are hanging wine berries, but no longer. Total Degree Day accumulation for the Vintage 2024 growing season stands at 2,503 Degree Days. We recorded total rainfall of 8.29 inches.

About all that is left after that is seeding the vineyard for Vintage 2025. Ernie managed to do that after the torrential rainfall of late October finally ran dry. Just a few hundred pounds of barley and winter peas is all it takes to hold the soil through the winter rains and fix nitrogen for the vines when they awaken next spring. He loads up the seed drill and drills every other row. He keeps permanent grass in the other rows, and that makes a good winter home for all of our beneficial insects.

Kindest Regards,

Dena & Ernie

Bipedal Cluster Pluckers

Amalie Robert Estate