Amalie Robert Estate Vintage Update: 2018 Harvest After Action Report (AAR)

Hello and Welcome, The is the 2018 Harvest After Action Report (AAR) from Amalie Robert Estate. A FLOG Communication. Bringing in the harvest is the last act of farming. It is the culmination of all that has happened since the last time you harvested. And harvest equipment is kind of like winemaking equipment. You own it all year long, but you only get to use it once a year. You will look pretty silly running the harvest trailers around the vineyard in mid-April, unless you are from down under. Farm equipment, on the other hand is used most every day during the growing season, but not so much during the dormant season. The dormant season is when you perform the sacred “equipment maintenance” ritual along with a few “Hail Marys” and prayers to the patron saint of all things mechanical – Rube Goldberg.

But it is the vertically integrated wine growers and winemakers (the “ers”) that keep busy year-round. And let’s not forget the marketers. Without whom, you would not be able to enjoy a fine and pleasant FLOGing on a semi-irregular and somewhat irreverent basis.

Enough about us, let’s explore the tons and tons of sublime wine berries that were brought in this year by the human harvesters. We will leave the winged and hooved harvesters (aka blighters) for another FLOG.

Of course, there is math, just no avoiding it as a farmer. So, pull a cork and sip-along. First off you will need a piece of scratch paper, unless you want a permanent record, then go ahead and write it on the table with a Sharpie. In the upper left-hand corner, draw a 5 gallon plastic bucket with a handle.

Now go ahead and write the number “20” inside the bucket that you just drew. This represents how many pounds of wine berries are harvested in any given bucket. Now to be sure this is just an average. There may in fact be one or maybe two buckets that actually do weigh 20 pounds, the law of large numbers will see to that. By far and away, most buckets will not contain exactly 20 pounds of wine berries. (How many months have 28 days? – All of them…)

Most will contain at least 20 pounds, so we have a little wiggle room when a bucket gets spilled or contains a compromised cluster that needs to be “sorted out”. Yeah we do that right there in the field for the rest of the clusters see. They feel shame.

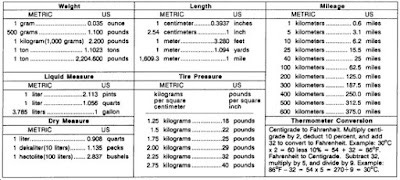

The harvest bucket is the keystone to making harvest work. So much is riding on this little piece of molded plastic with a half moon metal hoop precariously attached to the top. For Pinot Noir in particular, it takes about 4 clusters to make up a pound. You could say 4 ounces each, or if you are metrically oriented, that would be 454 grams divided by 4. Note: This is an exercise left to the metrically oriented reader.

Clearly, you can see which way we are oriented. (Note: Oreintated is not a real word. The same holds true for substainable, even here on the farm.). It‘s not that we are metrically challenged, it is just one more conversion to do when your synapses are already firing as fast as humanly possible. Even Einstein would tell you to write these conversions down for quick reference, so you could occupy your brain with more important matters. Like clusters per bucket, then buckets per harvest tote bin and followed-up with Ernie’s favorite measure: furlongs per fortnight.

And if we have done a good job in the field, any given vine will have about 12 clusters representing 3 pounds of wine berries. Now, you see where we are going. If a harvest bucket weighs in at around 20 pounds, this means there are going to be somewhere around 80 clusters in there. This is true for the metrically oriented reader as well, no conversion required - yet.

Here is where the math gets a bit more intense. If we harvest 80 clusters per bucket and any given vine has 12 clusters, how many vines are harvested for each two bucket human harvester trip to the harvest trailer? The old story problem brought back from the far, far away elementary school days. Well, the answer is “it depends”, which is mostly what they teach you to say in MBA school. If only we knew that as kids, we would have aced math class!

Assuming all the clusters on the vine are actually harvested, and you know some of them won’t make “the cut”, we can get between six and seven vines harvested per bucket, or let’s just say 13 vines for every pair of buckets coming up to the harvest trailer. But sometimes the winged harvester and the hooved harvester have visited the vine before the human harvester. This adds systemic variability and skews the entire multivariable equation in context of the time space continuum.

The long-range implication of that revelation is that we have about 55,000 vines to harvest. So that is roughly 4,250 two bucket trips to the harvest trailer. And to consider the human factor, we would say that is one human making 4,250 trips to the harvest trailer, or 10 humans making 425 trips to the harvest trailer, or maybe 20 humans each making 210 trips to the harvest trailer.

We go with the 20 human option, spread over a few weeks in the time space continuum. To give credit where credit is due, the human harvesters work very, very hard. It is physically demanding work and not well suited for the chronologically advanced. As most of you know, premium Oregon vineyards are situated on hillsides which makes running up and back down the rows more challenging. This adds a dimension of complexity that is clearly present in all of our wines.

A full day for any human harvesting wine berries is 100 buckets (50 two bucket trips) to the harvest trailer. That comes in as 20 pounds by 100 buckets for 2,00 pounds, or one ton. A metric ton is 2,205 pounds, and, well quite franc-ly, what do you do with that?

Now go ahead and draw a harvest tote bin just under the bucket. A harvest tote bin is 4 feet square by about 30 inches tall. Ours are white, so we know when we get them clean, but you can make yours whatever color you like.( Maybe a rainbow with a unicorn would be nice – parenthetically speaking). A harvest tote bin at Amalie Robert Estate should contain 36 harvest buckets and then a lid is snapped on to indicate to the yellow jackets that these wine berries are ours. Then we say the UK abbreviation for post office, which happens to be “P. Off”. Trust on this, Dena lived there and Ernie has never let it go. They speak English and we speak American. Good to know if you are planning a trip and need to ask someone where to “post” something. They will most likely tell you “P. Off!”

The key to the winery operating as smoothly as it was expertly designed by Mr. Munch, is getting 36 buckets (20 pounds each) of wine berries into each of these harvest tote bins. Now, go ahead and draw 36 buckets worth of wine berries in your harvest tote bin and then draw a lid on it. You can add a few angry yellow jackets (V. germanica most likely) buzzing about trying to sting people, or actually stinging people, or stinging you, depending on how you are oriented. Quickly draw an Epi-Pen if you are feeling like you may be going into anaphylactic shock. Whew, that was close.

Legal Disclaimer: If you publish your drawing and become rich and famous, we want a cut of the action.

There are three harvest bins on a harvest trailer that is hooked up to the tractor that Ernie drives to the winery to drop off full harvest tote bins and return with empty harvest tote bins. Ernie is inside a cab, so don’t draw any yellow jackets in there. But he does have his genuine USPS 1989 Montana Statehood commemorative stamp coffee mug full of morning accelerant if you want to draw that. A postage stamp in 1989 was 2 bits. Even in Two Dot, which is located in Wheatland County, Montana.

And now, the magic of 36 will be revealed for all to see. Just to the right of your harvest tote bin, go ahead and draw a fermenter. A fermenter has the same footprint as a harvest tote bin, but it is about 4.5 feet tall. Again, ours are white HDPE plastic, which makes it easy to see the wine berries and resulting wine. But to each his own.

Now, you don’t really need to know any of that, it’s called a red herring. Doodle one of those on your desk blotter, because you won’t have any space here. But what you do need to know is that our fermenters can only hold 1.4 tons (2,800 pounds when you ferment with whole clusters as we do, and you would too). Herein lies the lesson: 36 buckets by 20 pounds by 4 harvest bins fills a fermenter properly. And by properly we mean it is so full that we can get a warm (but not hot) fermentation to extract all the great aroma, flavor and texture, but not so full that the wine overflows and makes its way to the drain. You know, a proper fermentation – not too hot, not too cold and certainly not overfull. On the other side of the coin, an overfull fermenter is a sad, but self-correcting situation.

But wait, there is more math. We have 36 harvest bins. And that just so happens to be 12 trailer loads of 3 harvest tote bins. And those 36 harvest tote bins, at 4 per fermenter, will exactly fill 9 fermenters. How do you suppose that happened? Recheck your math on that furlong to fortnight conversion.

On the remaining open space of your paper, or the rest of the table, draw as many fermenters as you have room for. Now, fill them until all of the grapes are harvested or all of the fermenters are full, whichever comes first. Your mileage may vary.

The weather coming into harvest this year reminded us of the World Series. Those boys from Beantown won one, lost one and then they would simply not be denied. Even if it took 7 hours and 20 minutes to do so. It became a World Serious! Congratulations and ring up those folks at Gillette and get yourselves some razors.

We started The Great Cluster Pluck of 2018 with a warm, late September pluck for Ernie’s pre-sparkling wine project called the Bellpine Pearl. This wine is made from the wings of Pinot Meunier and Pinot Noir. The first vintage was 2015 and it was a white wine, and with 2018 we return to that style. Maybe, someday, it will actually be a proper sparkling wine, or Ernie will mess something up and it will be fizzy in the bottle. Until then, you will need a tall narrow glass, a straw and some form of eye protection (OSHA approved) to make your own bubbles.

Then, it rained. It was amazing and just what we were all hopping around the vineyard for - aka the rain dance. The first week of Okto-vember was cool and damp. Not enough to encourage the Botrytis, but enough to slow down sugar accumulation by rehydrating the wine berries. The best gift of all was to allow a little more hang time for aroma and flavor development. It was a gift from Mother Nature and all was right with the world.

The next week we were right back up in the 90 degree range. So much for a repeat of the wonderfully expressive 2007 vintage. The rest of October, just like those Red Sox, kept the heat on. It was GO, GO, GO and then GO some more! And so we did, 36 buckets per each. Vintage 2018.

The terms “indigenous fermentation” or “wild fermentation” refer to those select few individuals who choose not to add commercial yeast from a bag to their fermenters. We are included among those individuals. Instead, we rely on the yeast from the vineyard to start and complete our fermentation.

It is true, that the wine berries not only have indigenous yeast on them when the arrive at the winery, 36 buckets per harvest tote bin, they also have some other nefarious yeasts and bacteria. All of that gets mixed together, 36 buckets as whole clusters and 108 buckets as whole berries, into a fermenter and off they go! It’s a “Party in our Pinot”, microbially speaking.

All of this pre-supposes that you have successfully chosen days to process said wine berries when the power company has not chosen those very same days for “infrastructure maintenance" resulting in a loss of electricity. Fortunately, punchdown is done by hand, so no worries there. The other environmental concern to be aware of is when the State of Oregon lifts the backyard burn restrictions. That is usually at the end of October, and it becomes quite obvious who the closet pyromaniacs are in your neighborhood. They are all out in full regalia for opening day!

So, while all of this is very interesting and quite esoteric, you may be wondering how we know the indigenous yeast from the vineyard is going to ferment the wine berries. For an illustrative answer to that question we turn our attention to that horrible little insect, the fruit fly (Horribilis minimus).

Fruit flies, as annoying as they are, can teach us all a great deal about indigenous fermentation. Much like the yeast that ferments our wine, fruit flies seem to appear out of thin air. Two of the right fruit flies, or maybe just one of the wrong ones if you are (un)lucky can spawn an entire army that will colonize the winery in an exponentially reproductive fashion. We all know that 2 plus 2 is 4 and that 2 squared is 4, but 4 plus 4 is 8 and 4 squared is 16. Even Einstein’s theory of relativity informs us that time flies like an arrow, but fruit flies like a banana. Or was that Groucho Marx?

Yeast rely on cell division to reproduce, so none of that egg laying business. However, it would seem that the exponential population growth of both indigenous yeast and fruit flies are quite similar. It is a sad day when the first couple of fruit flies are spotted. From that point on, Ernie is somewhat militant, in an “A type” manner, about cleaning everything that has, or has had, contact with a wine berry.

Conversely, when you see the first carbon dioxide bubbles of fermentation, you are elated! Fermentation has begun! It actually worked! We were not so sure in 2006, with our first vintage in a brand new building. Two weeks is a long time to wait to see any sign of fermentation. We had fruit flies the first day for sure, but we had to wait for the indigenous yeast. Now that the building is inoculated with our own Amalie Robert Estate indigenous yeast, it just takes a couple of days or so and we behold the magic of fermentation. Often times through the purview of the fruit fly.

What gets measured is what gets done. That is a bit of wisdom Ernie picked up early in his career and it has served him well. Fully integrated and somewhat autonomous self-calculating spreadsheets track every vineyard activity and operation. A nickel is not a big deal, but multiply that little nickel by 55,000 vines and suddenly you have a meaningful number.

Ernie doesn’t start tracking the fruit fly population until it gets to about 1 million. Once it gets to 5 million, all of the fermenters should be full of indigenous yeast and actively producing carbon dioxide. Note: The vines are going to need that carbon dioxide next Spring, but in the meantime, Ernie has a plan.

Refer back to your diagram and notice the section with all of the fermenters. You probably drew them from a side view, and that is fine as you can now speckle your drawing with 5 million fruit flies. And don’t forget to put yourself in the picture. Maybe you are doing punchdown or washing the floor. Or maybe you just got stung, again… Kinda looks like a Jackson Pollock sort of thing. Well done, well done indeed!

And soon enough the fruit fly is interacting with your environment. From their point of view, you are interacting with their environment. Hard to say who is right or wrong, but a fruit fly in your ear or up the nose is clearly right out. And when they show up at your house, because they are in your hair and your clothes, you have performed cross inoculation - whether you knew it or not. And the whole cycle starts all over again, in your environment.

Ernie takes a more top down view. His view is looking down from directly above the fermenter. And he sees a piece of 4x4 HDPE plastic that sits on top of the fermenter and covers the wine berries.

He had these tops custom cut and they sit just inside the lip of the fermenter. At each corner there is just a wee little bit of a gap where they don’t fit snug. The fruit fly is predisposed to find this opening, and this is where they try to gain unauthorized access to the fermenting wine berries inside.

But they are greeted with the by product of indigenous yeast – carbon dioxide. A fermenter will produce about 14 times its volume worth of carbon dioxide. Ask anybody, that’s a whole lotta gas. With the tops in place, all of that gas has to escape from the 4 corners where the tops are not snug. And that is where the fruit flies mass for attack. But there will be no attack because they have all been asphyxiated. That’s a twofer for carbon dioxide. It’s not such a bad gas after all.

The other alternative is a Venus flytrap plant. Ernie first saw one of these in a winery setting while chatting with Steve Doerner at Cristom. We were delivering Pinot Noir wine berries to Cristom before we built our winery, and the significance that that plant represented was lost on us, at the time. The Venus flytrap plant is a poignant reminder of the sheer magnitude of the situation.

Eventually, about 4 to 6 weeks after harvest, the indigenous yeast complete their task and transform Fructose and Glucose into alcohol. They have produced a boatload of carbon dioxide responsible for killing most of the fruit flies and now lie dormant at the bottom of the fermenter, and on virtually every surface of the fermentation deck. They lie in wait, ready for the next harvest and the onslaught from a new battalion of fruit fly.

Then it was done. The end of October saw the Syrah and Viognier harvest, just before a nice shot of rain the next day. After the rain, the soil was perfect to drill in the fall cover crop. This gave Ernie a chance to get a jump on vintage 2019. The best laid plans…

If it has wheels or balls it will cause you trouble sooner or later. Today, this is in refence to tractors, Italian tractors in particular, to which Ernie owns three. One has steel tracks, and two have wheels. Out of the two with wheels, one has balls. The tractor in question has both wheels and balls.

Dena holding a pair of “Tractor Balls”

Off he goes, drilling away on a beautiful November day. It was simply perfect, the week of the ¡Salud!Pinot Noir auction planting our cover crop that will hold our soil through the winter rains and provide nutrients for our vines next Spring when it is tilled under. What could possibly go wrong?

Well, once Ernie got the tractor out of the 7.5-foot-wide row, he could clearly see what went wrong. The tractor balls were in place holding the seed drill to the three-point hitch, but he was missing a few lug nuts and a wheel stud or two.

Based on his 20 years of farming experience, and a few years of street racing, he knew what he needed to do. He also knew he had to get that tractor out of the field before the rains would most certainly arrive. Or, like back in Montana, wait until next spring to drive it out. It was a situation to focus the mind and provide a sense of urgency. What a time to be out of beer.

The decision tree went something like this. Order a new wheel, wheel studs and lug nuts, swap the tire onto the new wheel and remount on the tractor. Then finish drilling cover crop and drive the tractor out of the field before the rains made it a permanent fixture. As Ernie set this plan in motion, he remembered the words from his old boss at Microsoft - the Army guy. He said, “A plan never survives first contact with the enemy intact.”

It turns out that agricultural tractor wheel technology had changed over the past 20 years, and his style of wheel was no longer being produced. A glimmer of panic ensued. A call to the local dealer turned up a very small wheel that could be used to move the tractor, but not a permanent solution. The glimmer began to glow. The local Ag store had never seen anything like this wheel before. But they offered to build one out of scratch… Burning brightly now.

So, a call to the importer was the next step. The parts man was Clarence and while he was reluctant to deal with an “end user”, he finally relented to Ernie’s subtle “A-Type” ways. Any parts man worth his salt will ask for the serial number of the tractor as a defense mechanism. No serial number, no parts and goodbye. Ernie had his newly renewed insurance policy on the counter, thumbed through some pages and there it was. The serial number was the key to taking the next step.

Clarence was not impressed. He said the tractor came with 20-inch front wheels. Ernie confirmed his wheels were only 18-inch. “Well, then I can’t help you.” Ernie’s mind flashed back to the day he was standing at the Guigal winery talking with Marcel Guigal about Syrah clones. Think of something to say, and do it now!

“Well, the tire size is 280x70x18. Do you have any wheel that would fit that tire and my tractor?” Ernie’s question was met with a “Harumph.” But that happened to be the magic question that returned a part number! HA! This is going to work! But the next question foreshadowed things to come.

“Do you have one in stock?” Ernie asked, oh so gingerly. “Nope. The last one we sold was in 2006.” It turns out that no one in the United States had one in stock. And that if Ernie were to get one, it would have to come from the supplier, if they still had any. Being an Italian tractor, with both wheels and balls, the supplier was located in Europe, mostly likely Italy and that was a 2 week lead time, at best. If they had one. Cost approaching $1,000 all in, converted from metric.

Plan B arose like a Phoenix out of the smoldering ashes of the decision tree. It turns out, Ernie had a spare wheel from his other wheel tractor, that does not have balls. It is 100 horsepower, just no balls. The wheel leaked air, so he replaced it. The replacement wheel also leaked air, so he put a tube in it. But the wheel fit a 20-inch tire, not an 18-inch tire. However, the center mounting spokes were identical.

The local tractor dealer said that he knew a guy that could help Ernie with his problem. And would he be interested in checking out a new tractor while he was here? Off to King’s Industries to meet the key to this whole sordid affair. Ray King has a relatively small, but very well-kept machine shop not very conveniently located to the vineyard.

Friday afternoon, on the way to the ¡Salud! Pinot Noir auction, we met Ray King. Ray looked at Ernie’s handiwork on the 18-inch wheel and the nearly new 20-inch wheel and gave a quick nod. “I am not sure I can have it done today, but I am leaving town on Sunday, so I have to get to it before then unless you want to wait until next week.” “I can pick it up anytime tomorrow, if you can get to it,” Ernie heard himself say.

Saturday morning, he got the call. “Your wheel is done. You can come by and pick it up anytime.” Ernie thought to himself, either this Ray King guy is really good, or he has no idea what he is doing. Ernie was betting on the former. He wasn’t asking for a miracle, he was depending on one.

Sure enough, the wheel looked like it was just shipped from the factory. Ray explained how he tack welded a ring onto the good spokes, cut them off the wheel as one piece and then welded them into the 18-inch wheel. Ernie smiled and said, “I see you have done this before.” $175 dollars and 4 days later, Ernie was back drilling cover crop. Almost.

It turns out those wheel studs and nuts were as scarce as the wheel. So, it was another call back to Clarence. No serial number required this time, so it was a much shorter call. Add $150 for a set of 5 wheel studs, nuts and washers - Next Day air.

Back to Les Schwab to get the tire mounted onto the newly repaired wheel. Ray insisted the tire be taken off the wheel as he did not want the tire catching on fire while he was welding the wheel. Ray is the kind of guy that doesn’t run with scissors. Add $75 for a new tube, dismount and remount.

Now, Ernie had all the pieces to complete the repair. The glimmer of despair was replaced with the boldly burning fire of conquest! Pull out the floor jack, turn on the air compressor and get the impact wrench! We are going to mount this wheel! And so he did.

Every time Ernie goes to get in a tractor now, his precheck sequence has added responsibility. He must check not only their wheels and balls, now he has to torque their Italian studs and nuts.

Finally, the numbers. Let’s start with some serial numbers. While you are not likely to run across these unique sets of numbers, they are the real deal. If you happen upon them or they upon you, please let us know. Or your local law enforcement officials as they will know what to do.

260-75754

117-33556

B6258927

18401PZ163

3.141592653 (Actually this is not a serial number. It is Pi and goes on forever!)

And we have a NEW video to share! You can check out the Facebook page for the Dallas Oregon Sheriff’s department here. Recognize anyone? See something, say something.

https://www.facebook.com/PolkCountySheriffsOfficeOregon/posts/2174175509294985?__tn__=-R

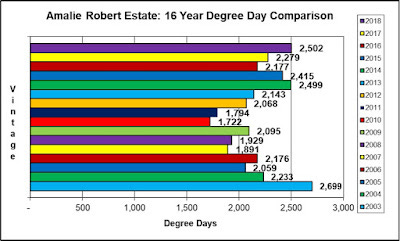

And the farming numbers. “Hotter than the hubs of Hell” was the expression Ernie’s grandmother, Bert, used to say. Ernie just says, “Twenty-five hundred. You are a smart guy, you figure it out.” Way too farming hot to grow elegant Pinot Noir. Syrah, yes of course. A manly wine in touch with its feminine side. But Pinot Noir, not so farming much. But there it is. 2,502 degree days. Not since the horrific 2003 vintage (2,699 degree days) and the also ran 2014 vintage (2,499 degree days) have we been subject to such intolerable growing conditions.

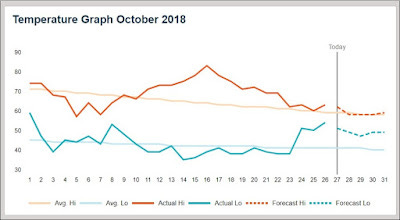

Right. The last set of growing season Degree Day numbers we shared were April through August. The degree day accumulation through August was 1,954 Degree Days. Not so bad, pretty good overall. But what we thought would be a more moderate fall, morphed into a warm and exceedingly dry end of the growing season.

September added 342 Degree Days and October added 205 Degree Days for a 2018 vintage total of 2,502 Degree Days. You can check out the 16 year growing season Degree Day chart below to see how vintage 2018 stacks up. Channeling vintage 2007, 2010 and 2011: “Miss me yet?”

And it was dry, dry, dry as a popcorn flatulent. The first 2 weeks of September gifted us 0.51 inches of precipitation. However, the 90 day period preceding that September shower was one of the most beautiful summers to be had in Oregon, and all of those days were without precipitation. So that rainfall really didn’t get down to the roots. The opportunistic grass, gentle fall breezes and Photosynthetically Active Radiation (Farmer speak is PAR, you know it as sunshine) took care of that moisture in short order. Harvest began nonetheless on September 17thas we were sure (praying) more moisture was in store for us.

October delivered on that promise. The 6th of October registered 0.44 inches of rainfall. That was 3 weeks after the last 0.51 inches of rain, and as they say, too little too late. But we are farmers, and we just take it. Here is the second kick from our friend the mule. The high temperature in October was 82.4 degrees. That’s not bad, you think out loud. That temperature was recorded on the 16thof October. A little late in the game for that kind of heat. Hey Frank, can you get us some more beer and sunscreen?

So, climatically speaking, we have just about an inch of rain from June 11th through October 28th. Heat accumulation from the same period, June through October, was 1,717 Degree Days. Simply unprecedented. And let us remind you that when we planted the Pinot Noir, Ernie was keen on the deep rooting proclivities of 5C rootstock as we were going the dry farmed route. We will talk more about 5C, but we are not there yet.

At this juncture, we know what you are thinking. Ernie is just whining about over extraction, the demise of elegant, lower alcohol Pinot Noir and you would be right. But he is also waiting out Mother Nature for his Syrah and Viognier.

Everyone thought Ernie was daft for planting Syrah in the first place. He took the first class, one-way, nonrefundable ticket all the way to crazy town by grafting those vines onto the deepest rooting, latest ripening rootstock available to him – 5C.

Everyone said 5C will never ripen Syrah. You will be lucky to get Pinot Noir to ripen on 5C. That rootstock sends the roots too deep looking for water and they will not experience the drought condition needed to stop growing leaves and start ripening fruit. The vines will be stuck in a vegetative cycle and direct all their energy to growing more leaves, not ripening the fruit. Everyone said you will not be successful growing Syrah in the Northern Willamette Valley.

If you see “everyone” tell them we said “hello”.

So that “ungrowable” 5C rootstock underlies most of the vineyard at Amalie Robert Estate from Chardonnay, Pinot Meunier, Pinot Noir and, of course, Syrah. Wine berries grown on our sedimentary Bellpine series soil and 5C rootstock have been the “hot ticket” these past few vintages.

While everyone is freaking out over skyrocketing sugar accumulations from lesser, shallow rooting rootstocks, Ernie is planning his work and working his plan. He is about 20 years in on his plan and has seen most of the idiosyncrasies and agricultural vagaries. But every year is a new set of answers, even though the questions remain the same. Labor is a new and challenging issue each and every year. That’s farmin’.

And if you refer back to our handy-dandy Amalie Robert Estate, site specific Degree Day chart, you can see how the 5C rootstock with deep, moisture extracting roots, can help moderate these arid conditions of the last several years. In fact, 5C and own rooted grapevines are very similar in their rooting proclivities.

Mother Nature does have a sense of humor, or is that irony?. The 29th of October gave us over 2 inches of rain, and that is when Ernie “pulled the trigger” on the Viognier and Syrah-ah-ah-ah-ah!

We apologize for the lateness of this communication, but we had a little more “action” than we were expecting this year. We endeavor to be more timely for vintage 2019. Hey, we are pruning the vines right now!

Kindest Regards,

Dena & Ernie